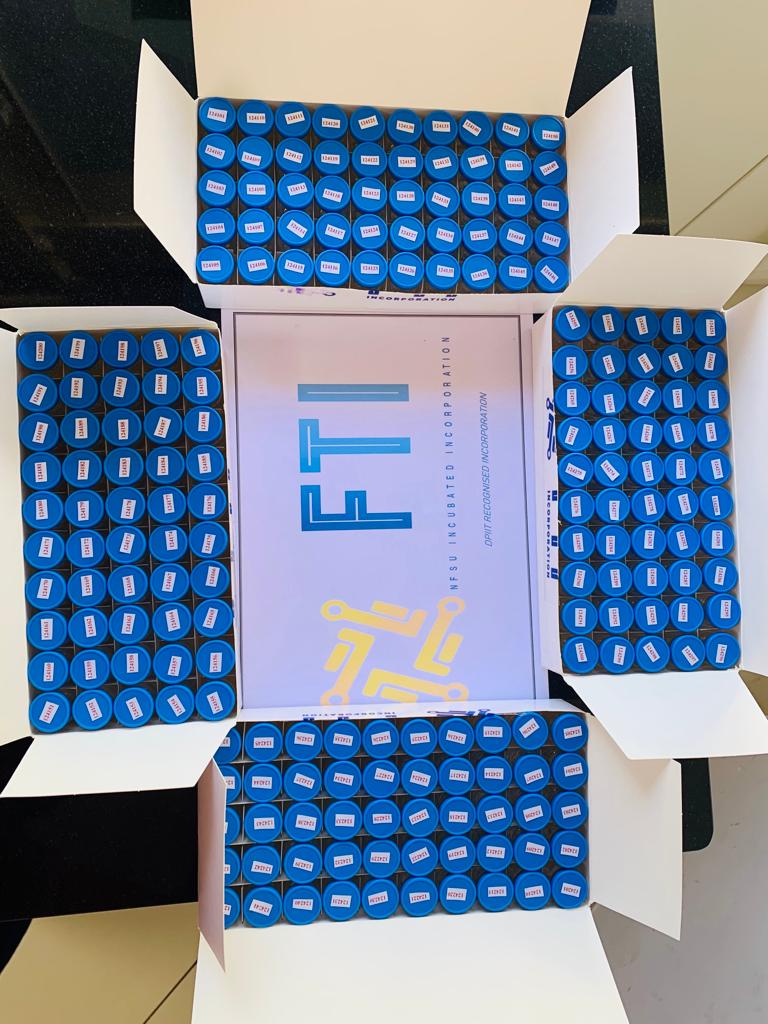

Visual Inspection Knapp Testing Kit: Give Your Customers the Quality they Deserve

Many folks in the manufacturing and production industry find it time-consuming, costly, and difficult to ensure the highest standards of quality and reliability in their products. But they do not have to worry anymore! With our Visual Inspection Knapp Kit, there’s a comprehensive solution to meet the uncompromising demands of quality assurance across various industries.

What is the Visual Inspection Knapp Kit?

The Visual Inspection Knapp Kit is a state-of-the-art tool designed to simplify the inspection process and increase product quality. Combining advanced technology with intuitive features, it delivers accurate and effective visual inspections.

How Does it Work?

Advanced Imaging Technology

The Knapp Kit is our advanced imaging tool that takes high-resolution images of products, parts, or materials for inspection.

Automated Analysis

The Knapp Kit employs automated analysis algorithms that quickly pick up defects, inconsistencies, or abnormalities thereby speeding up the inspection process as well as reducing the likelihood of human error.

Real-time Feedback

Real-time feedback is a special feature of the Visual Knapp Kit, which provides instant quality insights. This further facilitates timely corrective actions and process improvements.

Key Features and Benefits

Enhanced Accuracy

The Visual Inspection Knapp Kit is unique because of its unrivaled precision in the detection of defects. This means that even the slightest unnoticed flaw can be detected and fixed.

Improved Efficiency

Our Knapp Kit automates the inspection process to cut down the inspection time and labor costs, thereby improving productivity and throughput simultaneously.

Comprehensive Inspection

The Visual Inspection Knapp Kit is a multipurpose tool which not only covers surface flaws but also dimensional variation. Thus, it accommodates diverse needs for quality assurance.

Customizable Solutions

We understand that all industries and applications have unique inspection requirements. This is why we pack our Visual Inspection Knapp Kit with feature-rich customizable solutions, taking your exact needs into consideration.

Our Products and Services

Challenge WIT Knapp Test Kit

Ideal for full field visual inspection as our core product.

Calibration Standards for Automatic Visual Inspection Machine

Keeps your machines working in optimal precision.

Calibration Standard for Leak Test

Important for ensuring that your containers are not compromised.

Simulated Media Kit

It offers insight into the kind of defects that may be encountered during production.

Support Services

- Real-Life Simulation of Production Defects: Simulate real-life defect situations to improve training and preparedness.

- Audit and Inspection Support: We also help during external quality audits and inspections.

- Training Programs: Practical or virtual sessions for usage of the kit effectively.

- Documentation Support: End-to-end solutions to all documentation needs for effective regulatory compliance.

Product Container Range

We offer a wide variety of containers to meet the diverse needs of our clients:

- Clear/Amber Tubular and Moulded Vials (1 ml to 500 ml)

- Clear/Amber Cartridges (1 ml to 50 ml)

- Clear/Amber Ampoules (1 ml to 25 ml)

- Plastic Vials (Eyedrops/Eardrops)

- IV-Infusion Bags (25 ml to 2500 ml)

- Clear/Amber Pre-filled Syringes (0.1 ml to 25 ml)

- Plastic Ampoules

- Glass Tubes

- Capsules and Tablets

Surrogate Product Range

Our surrogate products are designed to mimic real-world defects and conditions:

- Oligonucleotides/Protein & Peptide Injections

- Simulated TSB with Varying Degrees of Haziness

- Viscous Colourless Solution (Oily Injection)

- Albumin Infusions/Blood Plasma Injection

- Lyophilized Powder (White/Cream/Yellow

- Suspension Products (Vaccines/Antibiotics

- Aqueous Coloured Solutions (Various Colors)

- Viscous Coloured Solutions (Various Colors)

- Lyophilized Cake (White/Cream/Yellow

- Aqueous Colourless Solution

- Rifampicin

- Emulsion

Industries Served

Manufacturing

Improve product quality during production processes, from automotive components to consumer electronics.

Pharmaceuticals

Compliance with strict regulations and product integrity must be safeguarded in pharmaceutical production.

Food and Beverage

Detect contaminants, defects, and foreign objects for the purpose of food safety and quality in food processing and packaging.

Key Features and Benefits

We are dedicated to assuring superior quality. Our Visual Inspection Knapp Kit guarantees that your products conform to the most stringent quality, reliability, and regulatory standards. Plus, we provide

Expertise and Experience

Cutting-Edge Technology

Customizable Solutions

Reliability and Accuracy

If you want the Visual Inspection Knapp Kit with the highest standards of quality, efficiency, and reliability, we are your best bet.